Marty Jones has spent a good chunk of his life now preaching the value of canned beer -- at least more than most of us probably have.

He was one of the founders of the canning effort at Oskar Blues Brewery -- which in 2002 was the first American craft brewery to brew and can its own beer. Now he's working with Cask Global Canning Solutions, a company that recently donated a micro-automated canning system to Metropolitan State University for use in its beer industry program and in Tivoli Brewing Co.

"It's a very focused, high-level education program for men and women who want to get into the beer trade, and we like to support those things," Jones said, watching as a handful of MSU students canned Tivoli's Brut IPA. "We're big believers in it, and it's gotten bigger and bigger of course, and we've lead a cultural overthrow of beer culture, American craft brewers. Now things that were once scorned in America years ago are now eagerly embraced by countries around the world."

Cask has put around 900 micro-canning machines in 60 countries.

The one recently donated and installed at MSU costs about $75,000. In addition to the expensive equipment coming for free, MSU will make money off of it. Tivoli, which sits on the campus and is connected to the student union, is paying the university to use it as would pay a contractor. The brewery is also staffing the canning line, and those staff members are training the students.

It's real-world, firsthand commercial brewing experience right on campus in a skill area that's becoming increasingly important.

"More and more breweries now, they understand the beauty of cans. They start with cans," Jones said. "They're the ultimate freshness-keeping package. They provide full protection from light and oxygen -- those are the two biggest enemies to fresh beer. They're super portable. The weight of a bottle of beer -- in shipping, a third of that weight is the bottle itself. So with cans, you get about 30 percent more beer on a truck, so you shrink your fuel cost, your fuel use. The packing is much smaller and light-weight. Everything is recyclable, and cans are welcome in places where bottles are not."

There are around 90 students in MSU's beer industry program. It offers two bachelor of science degrees, one in brewery operations and one in craft brewing and pub operations. It involves courses in chemistry, biology, business, management, engineering, law, marketing and economics, as well classes in MSU's hotels, tourism and events program.

And if you're wondering if age is an issue, the answer is "sort of." Tim Carroll, associate director of media relations at MSU, said the students working in the canning lab are 21 or older. Some younger students in more advanced classes need to get an exception.

The beer industry program also offers a minor and a certificate in brewery operations, which are seven classes each.

"Canning is really where beer packaging is headed," beer industry program director Scott Kerkmans said. "Obviously bottling is still important, kegging is still really important, but Colorado's at the forefront of innovation in packaging, with canning really starting here. So many more people in Colorado are accepting of cans for their quality beer, and as that wave kind of spreads throughout the country, our graduates will be better prepared than others simply because they'll have the opportunity to take that knowledge on the cutting edge and move it into other markets."

The program is about six years old and Kerkmans says most graduates have stayed in Colorado so far, though some have left for places like San Diego and Seattle and he anticipates more will do so as the program becomes more well known and as the Colorado market gets even more crowded.

A lot of graduates think they want to start their own brewery, but some realize through the course of their studies that it's not for them, Kerkmans said. That's why MSU's program offers such a wide variety of courses and experiences. Students could go into production, management, sales, marketing, engineering. The goal, he said, is to prepare them for anything.

Just downstairs from the canning line, MSU has a quality assurance and quality control lab that Kerkmans called one of the best in the state among craft breweries. (Obviously Coors has a very good setup.) There's "a little bit of microbiology living in the space," though right now students are primarily doing chemistry in there. MSU is hoping to build more room for microbiology in the next level down. (Unrelated note: their exploration of that space lead them to staircase down to nowhere and some bones, which turned out to be chicken bones.)

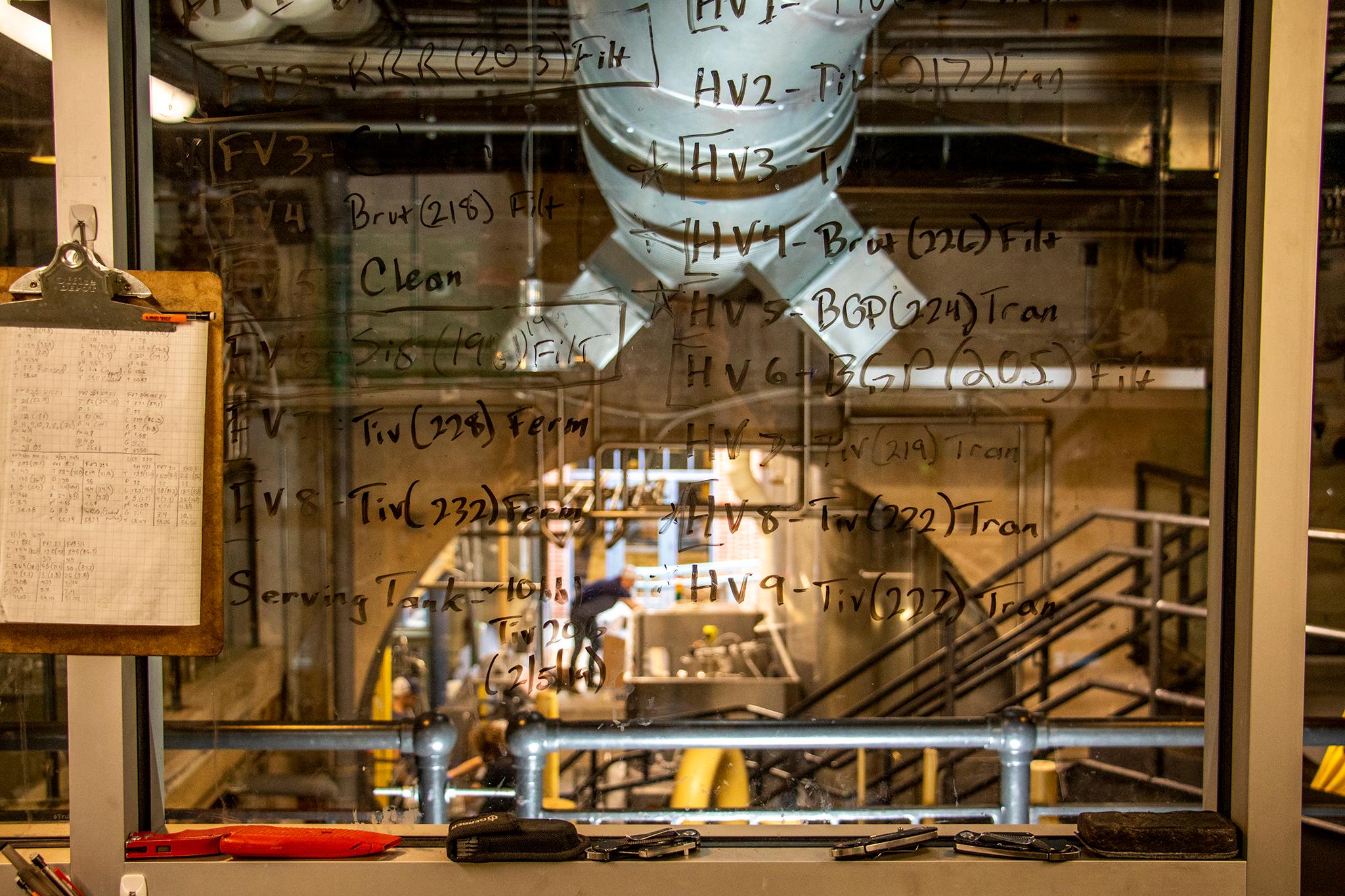

The lab -- like the canning and bottling area, lined with plexiglass to show and protect the historic brick structure underneath -- also has a "clean-in-place" room and a production lab where students are brewing on small systems for 10 to 15 weeks each semester. Class size in the lab is limited to about 18 students.

"I think we're doing some really innovative things here. We're not a science-based program, but one of the things we heard from the industry -- and that's really how we built our program, was hearing from the industry what they needed out of graduates -- one of the things we heard was these small- and medium-sized craft breweries really don't have the ability to effectively test their beer from a quality perspective," Kerkmans said. "... They really get to see that commercial aspect and what does the industry really need to ensure quality.

"Because that's gonna be the breweries that survive, are the ones that make quality beer, and our students will be exposed to that process."